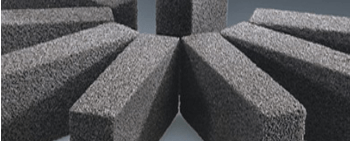

← About cellular glass

Cellular glass is an environmentally friendly thermal insulating material with unique properties and characteristics.

No other thermal insulator isn’t equal to it on reliability and durability. An analog, which would have such unique properties, isn’t still invented. For persuasiveness we give a comparative analysis of cellular glass and other thermal insulators.

Cellular glass is an environmentally friendly thermal insulating material with unique properties and characteristics.

No other thermal insulator isn’t equal to it on reliability and durability. An analog, which would have such unique properties, isn’t still invented. For persuasiveness we give a comparative analysis of cellular glass and other thermal insulators.

What thermal insulator is better?

So, we compare the properties of cellular glass, and other heat insulators: polystyrene, glass wool and stone wool.- Cellular glass has such a property as durability. Warranty period of operation of this thermal insulator is at least 100 years. Fibrous materials under certain conditions start to crumble after only ten years.

- Cellular glass has all the properties of the glass and is substantially incompressible material, unlike fibrous insulating materials. And that means can’t be deformed.

- Cellular glass can’t be destroyed by high temperatures (heat resistant 400ºC). While as polystyrene materials fear heat. In addition, cellular glass - is the only heat insulating material, which may be used in nuclear power plants.

- Cellular glass, unlike other types of thermal insulators, is not afraid of water, because it doesn’t absorb water. It can’t get wet or moldy. Due to waterproofing, cellular glass becomes a barrier to moisture, which doesn’t get the metal parts of the construction. Thus, the corrosion of metal isn’t possible.

- Cellular glass doesn’t burn and doesn’t absorb flammable liquids (oil and liquid coolants).This means that, unlike other types of heat insulating materials, the situation with fire is impossible.

- Cellular glass is resistant to biological effect. Rodents and bugs won’t appear there ever.

- Cellular glass is completely harmless and eco-friendly (which is not true for other insulators).

We can continue this analysis, but this brief comparison shows that the foamed glas, in comparing with other insulators - is the product of the most cutting-edge technology production of modern thermal insulating materials.

Manufacturing of foamed glass

Cellular glass is obtained by foaming the glass with the carbon. Thus foamed glass as solid suds, is a molecular entity of a plurality of glass sealed bubbles. This structure determines the low density of insulator and its thermal insulating characteristics.

Manufacture of thermal insulator cellular glass has two stages.

1. Ordinary glass is grounded into a powder (in a flint mill).

2. Foaming and annealing. During foaming agents such as CFC or HCFC, which destroy the ozone layer of the planet, are not used.

Environmentally friendly thermal insulator

cellular glass is characterized by features such as ecological cleanliness and sanitary safety.

This heat insulating material is widely used for insulation of industrial alimentary refrigerating installation, insulation for tanks and vats used in the production of beer, wine and dairy products.

Fiber materials (slag wool) have needle-like dust, which causes severe illness after contact with skin and respiratory system. But this dust can do harm to builders not only during construction process, if the builders did not put on respirators and strong gloves. After a time, the fibers crumble and turn into a needle-like dust.

Fiber materials (slag wool) have needle-like dust, which causes severe illness after contact with skin and respiratory system. But this dust can do harm to builders not only during construction process, if the builders did not put on respirators and strong gloves. After a time, the fibers crumble and turn into a needle-like dust.

Polystyrene is susceptible to the pathogenic decay process of polymers to free radicals;

Polystyrene is susceptible to the pathogenic decay process of polymers to free radicals;

Ru

Ru Ua

Ua De

De Pl

Pl